Introduction

ARIS WPS is a revolutionary web edge sensor technology that employs fiber optics to accurately determine the position of a web material irrespective of its material properties. This edge sensing principle is unique and provides a true, absolute web position measurement. The working principle of the web edge sensor is as follows. Light from an array of infrared LEDs (or laser diodes) is projected on to the web surface. The light that intercepts the web get scattered in all direction and this scattered light is spatially filtered using the fiber optic elements within the sensor. The filtered light is then projected onto a camera sensor. The edge position is determined by processing the output of the camera sensor using sophisticated digital signal processing algorithms in real-time.

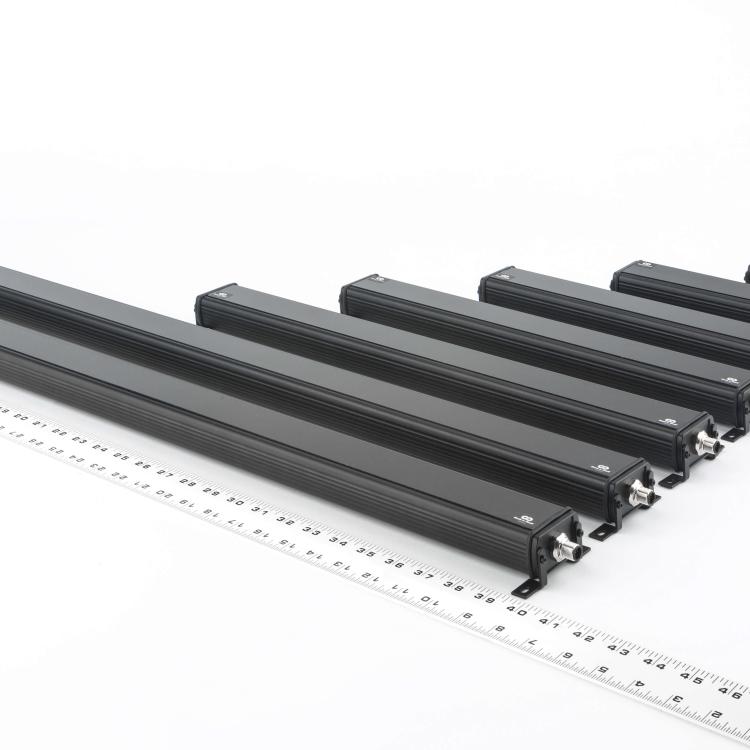

Web Edge Sensor Specification

Four sensor widths that are currently available include 16 mm, 48 mm, 221 mm and 440 mm. The sensor head includes an infrared filter, a spatial filter based on fiber optics, a one dimensional camera sensor and infrared light source. The camera sensor has a resolution of 63.5 micron or 125 micron based on the sensor model. ARIS WPS 16 has 256 pixels while the ARIS WPS 48 has 768 pixels, both with 63.5 micron resolution. ARIS WPS 221 and WPS 440 have a resolution of 125 micron with 1792 and 3584 pixels respectively. The infrared LEDs have a peak wavelength of 850 nm. Because of the computational complexity the signal from the camera sensor needs to be processed with a dedicated sensor processing unit which is located remotely from the sensor head. Up to 10 m long cable can be used with the sensor head enabling remote installation of the sensor head from the sensor processing unit.

Web Edge Sensor Performance: Experimental Procedure

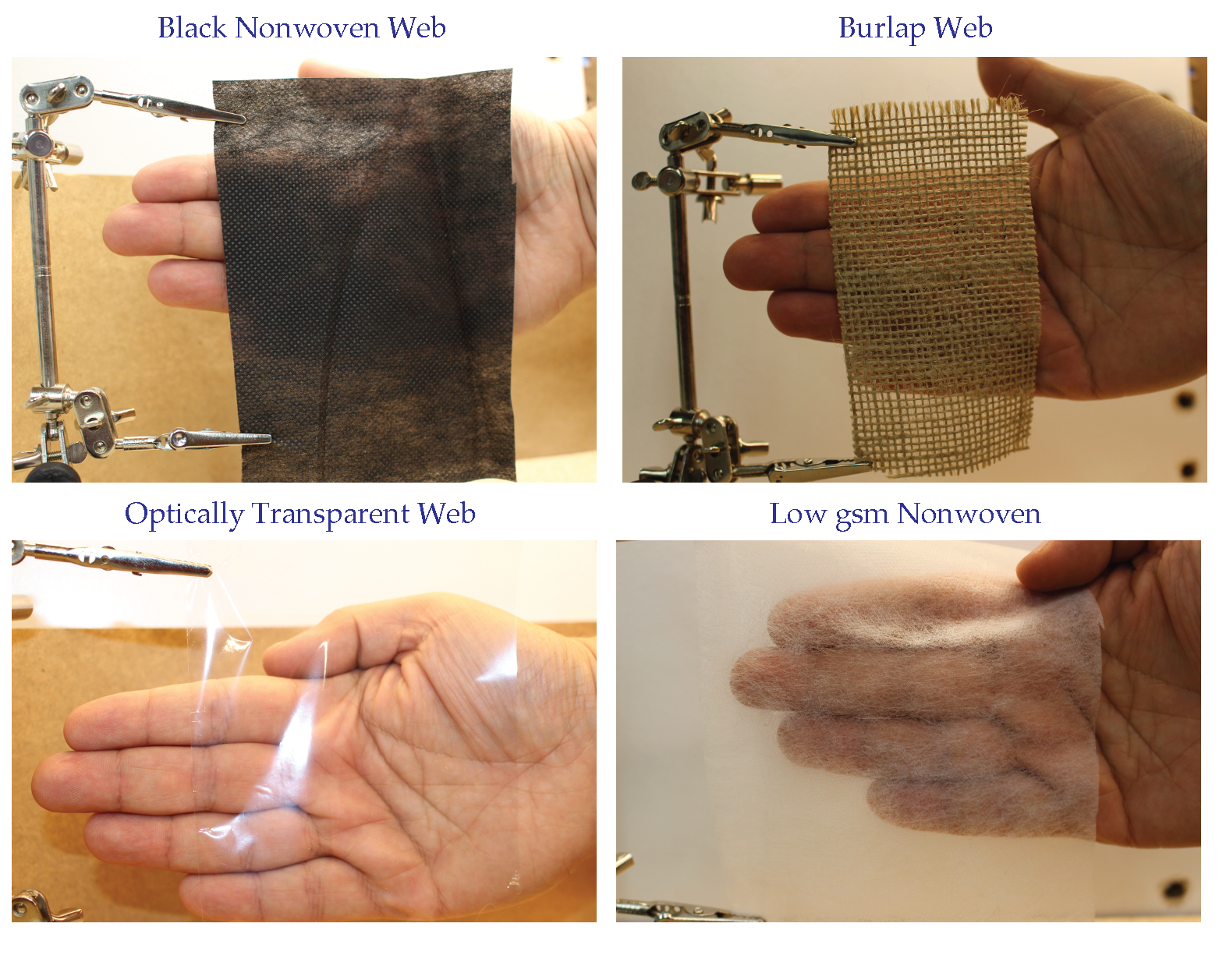

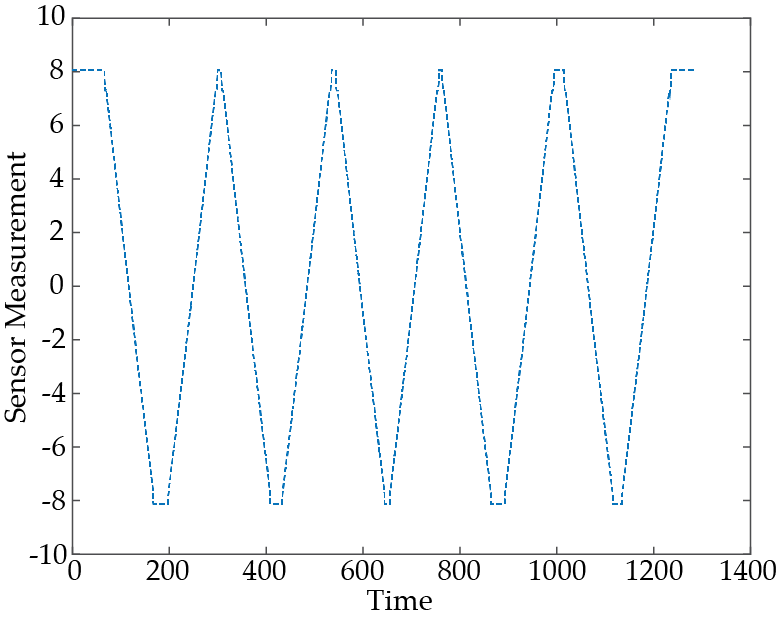

The working principle of the web edge sensor enables the sensor to detect any type of material without any calibration. In this white paper we shown experiments with four type of materials (see Fig. 1) to highlight the sensor's ability to work with different materials. These materials include a (1) a low basis weight nonwoven web that is highly porous, (2) an optically black nonwoven web with low optical properties, (3) a clear film with low opacity, and (4) burlap a textile material which is significantly porous. All these materials are troublesome to existing sensing technologies because material properties significantly affect the amount of signal attenuation. An experimental setup (see Fig. 2) equipped with a high precision motor stage which moves the web material back and forth is used to quantify the sensor performance. The edge sensor is mounted on the experimental setup with an ability to change the working distance. Even though the sensor is design to work with web materials at an ideal working distance of 5 mm to 10 mm, the work distance is increased to 20 mm to understand the performance of the sensor. For the set of experiments with each web material, the web on the motor stage is moved back and forth (as shown in Fig. 3) several times during a experiment while the motor position data and sensor edge position data recorded.

Sensor Performance: Experimental Results

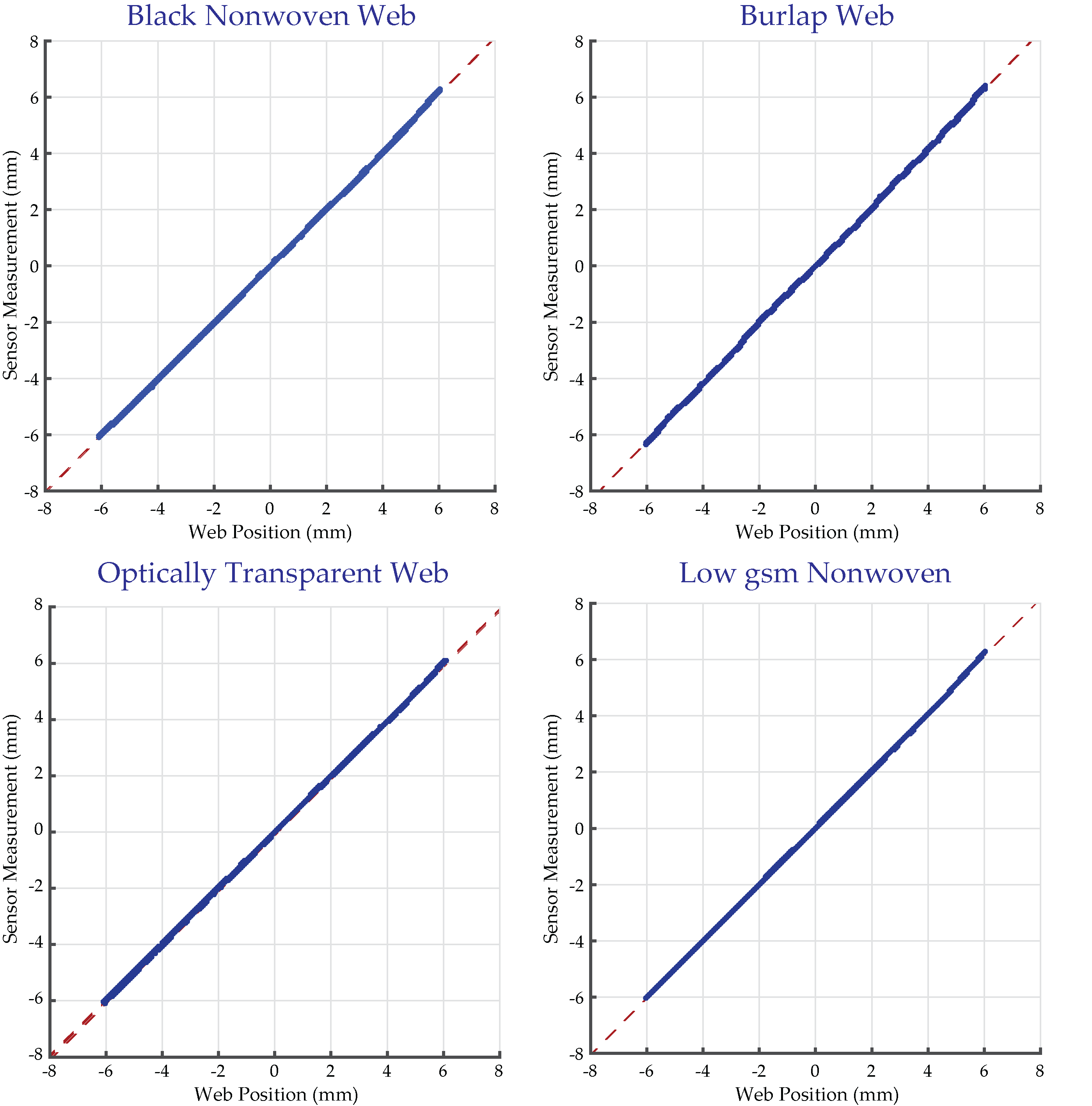

Fig. 4 show representative sample of experimental results with 16 mm sensor for the four different web materials. Sixteen sets of data were collected positioning the motorstage to move back and forth eight times. The step size and the motor speed was chosen such that every single pixel is covered during every experiment. Data from all sixteen experiments are superimposed into a single plot. The abscissa shows the web displacement measured using the motor position sensor and the ordinate shows the web edge measured using our sensor. Both the axes are represented in millimeters. The blue dots in the plots are the actual measured data and the red dashed lines are the linear fit for each set of experiments. All the experiments showed excellent precision and accuracy of the sensor and sensing principle. As seen from the plots the accuracy (slope and bias), linearity, precision and repeatability of the sensing principle is unaffected by the material properties.

The slope, bias and linearity of the measurement for the four sample materials are summarized in the table below. The slope of the edge sensor measurement, which is within 1.4% of the ideal slope of 1, as well as the non-zero bias of the measurement clearly shows the exceptional accuracy of the sensing principle. Note that the bias value is less than the resolution of the sensor, which is 0.0635 mm, which indicates the sensing principle doesn't affect the bias. The R-squared value, the quantification of the goodness of the fit, is close to one which shows that the measurement is highly reliable, linear and unaffected by the material properties.

| Web Material | Slope | Bias (mm) | R-squared |

|---|---|---|---|

| Black Nonwoven Web | 1.00852 | 0.05013 | 0.99914 |

| Burlap Web | 1.04126 | 0.00238 | 0.99970 |

| Optically Transparent Web | 0.9950 | -0.05111 | 0.98326 |

| Low gsm Nonwoven | 1.01306 | 0.05218 | 0.99833 |

Conclusion

The experimental results show, unlike conventional sensors, the material properties do not affect the accuracy and precision of the web edge sensor. The edge sensor accurately measures the edge position with opaque material, porous web material, nonwoven web material, transparent web material. Similar results are also seen with the 48 mm sensor. And similar results were also observed with other materials such as paper, plastics, foil and films.